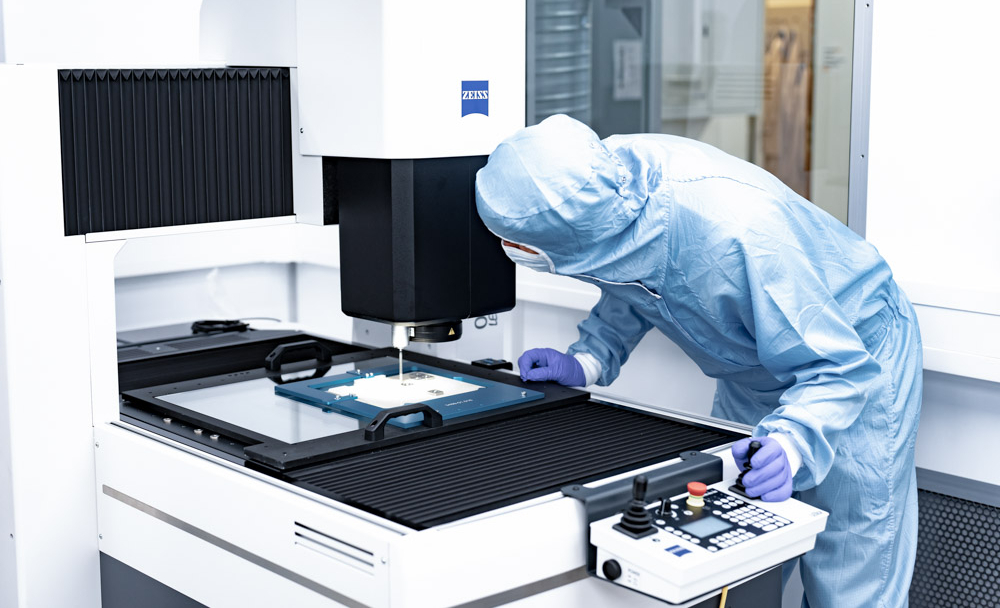

Micro-assembly in ultra-clean environment

MPS operates ISO 5 and ISO 7 cleanrooms. These facilities are used to manufacture delicate components that require exceptional cleanliness, from assembly to final packaging.

Thanks to clearly defined processes, highly qualified personnel, and state-of-the-art instruments, we are able to meet the demanding requirements of our customers in complex markets such as the medical and semiconductor industries. We thus guarantee systems that stand out not only for their precision and small size, but also for their cleanliness.

ISO 5 cleanroom

Since 2023, MPS has been operating an ISO 5 clean room for the assembly of ultra-clean components. Custom-designed to meet the high standards of the semiconductor and electronics industries, it is essential equipment for preventing the contamination of delicate parts.

In this room, where particle density and organic contamination are extremely low, we perform operations such as brazing, ultra-high vacuum (UHV) baking, GC-MS analysis, magnetization, and much more.

<0.1 ng/L

Volatile organic contamination9.16x10-8 mbar

Ultra-high vacuum baking3'520/m³ @ 0.5 µm

Particle density

ISO 5 equipment

- Vacuum baking: Particle elimination in a nitrogen atmosphere at a pressure of 9.16 x 10-8 mbar

- Cleaning: Delicate cleaning of critical components

- Brazing: Ultra-precise assembly of components under pressure and high temperature

- GC-MS: Analysis of contamination level after vacuum baking

- Assembly: Precise positioning within 2 μm of highly magnetized components

- Magnetization: Magnetization of components up to saturation

- Calibration: Magnetic field homogenization across units

- Metrology: Component inspection in controlled environment

ISO 7 cleanroom

In addition to the ISO 5 clean room dedicated to the semiconductor market, MPS has an ISO 7 clean room covering an area of over 200m2.

This room is used to assemble and solder miniature components for implantable electromechanical devices such as peristaltic pumps and other highly complex cardiac, orthopedic, and urological devices.

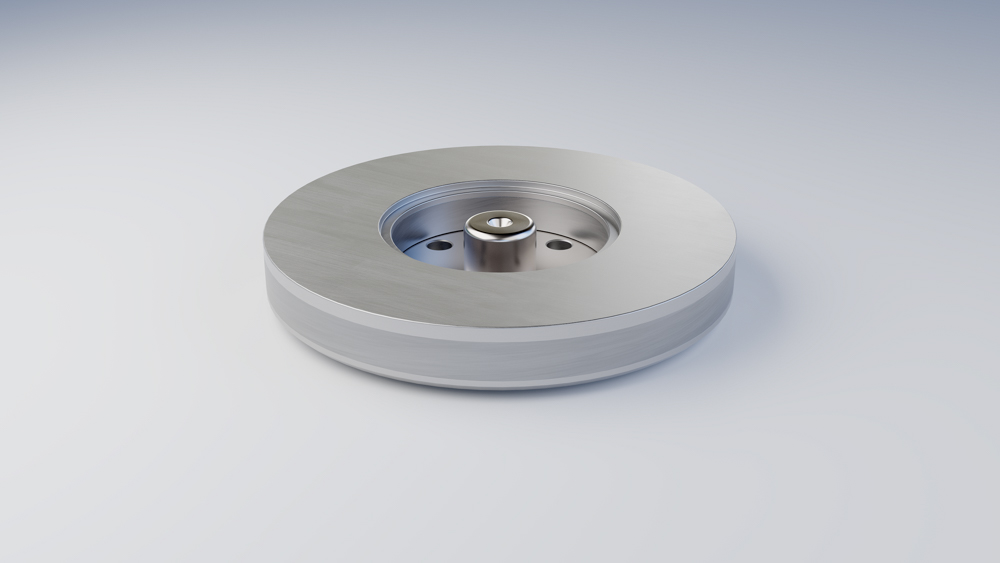

Mutli-layer assembly

In recent years, MPS has specialized in manufacturing multi-layer parts of exceptional precision, quality, and cleanliness used in the inspection of semiconductor components. Assembled on a ceramic substrate with a tolerance of ±2 µm, these components form a system that enables our customer to create high-performance mask and wafer inspection equipment.

These systems undergo various stages in the ISO 5 clean room, including brazing, vacuum baking and magnetization. During the micro-assembly process, magnetized components are assembled with a precision of less than 10 µm.