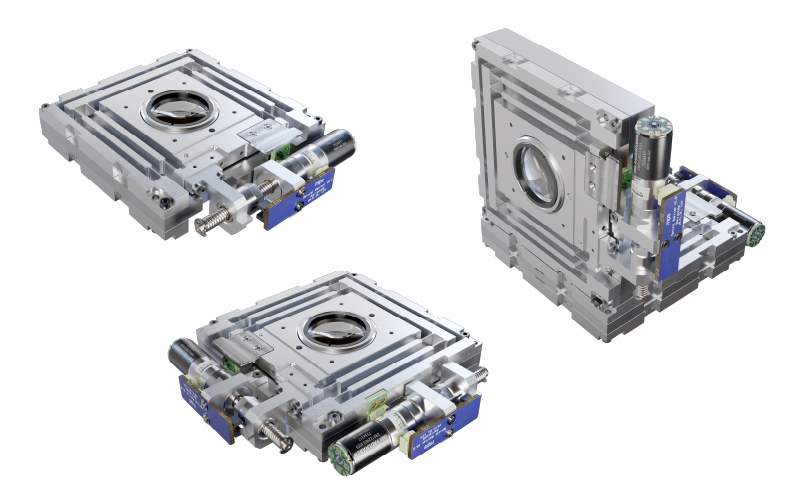

Multiaxis micropositioning stage

The motorized multiaxis micropositioning plate is engineered to deliver exceptionally smooth displacements over several millimeters, making it a game-changer in precision motion control. Using smart flexure elements, this modular solution provides unparalleled accuracy and stability on every axis.

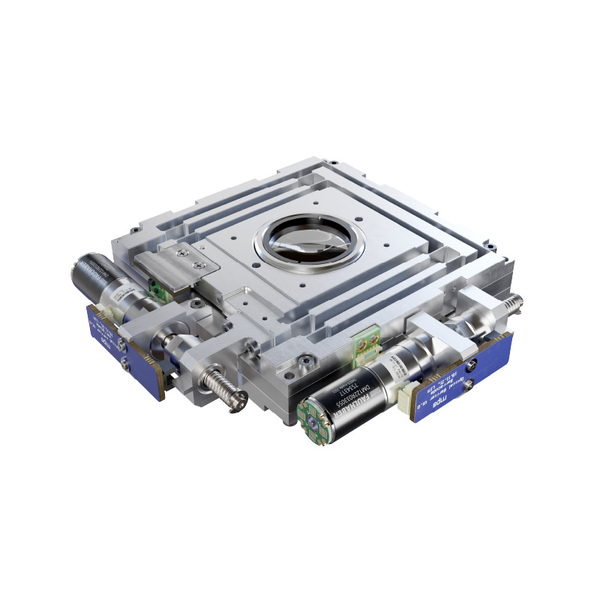

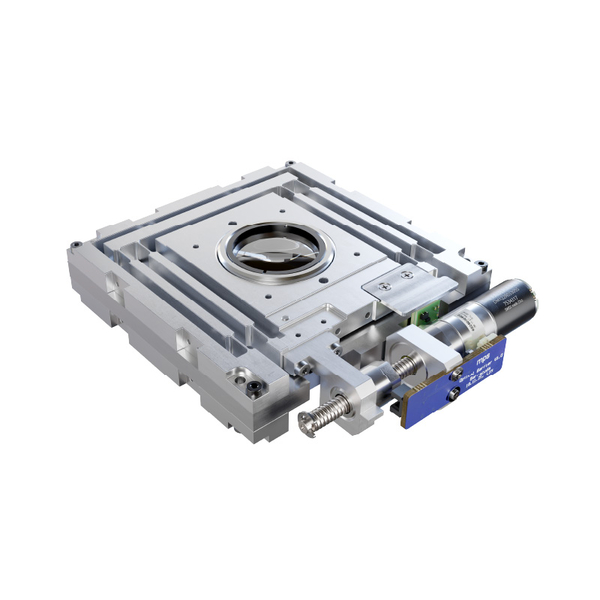

Driven by two micro motors strategically positioned at the edges of the assembly, the design remains ultra-thin, making it ideal for through-hole configurations in optical applications requiring precise transmission.

The innovative symmetry of the flexure plates allows for a range of mechanical displacements, enabling unique combinations that can be tailored to your needs. Whether you require extended strokes, precise X-Y stage movement, an additional Z dimension for an X-Y-Z system, or independent lateral displacements of two objects, our multiaxial micropositioning stage is designed to adapt.

Scalability is at the heart of this design. By adjusting a few key dimensions, the multi-axis micro-positioning plate can be customized to meet the specific requirements of applications that demand smooth motion, long-lasting durability, and maintenance-free, repeatable positioning.

주요 기능

| Stroke (X, Y, Z): | ± 3 mm |

| Resolution: | 0.15 µm |

| Motor: | Stepper DM1220 |

| Gear ratio: | 5:1 |

| Lens diameter: | 26.4 mm |

| Drive mechanism: | MPS ball screw |

| Dimensions: | 100 (x) x 100 (y) x 18 (z) mm (X-Y version) |