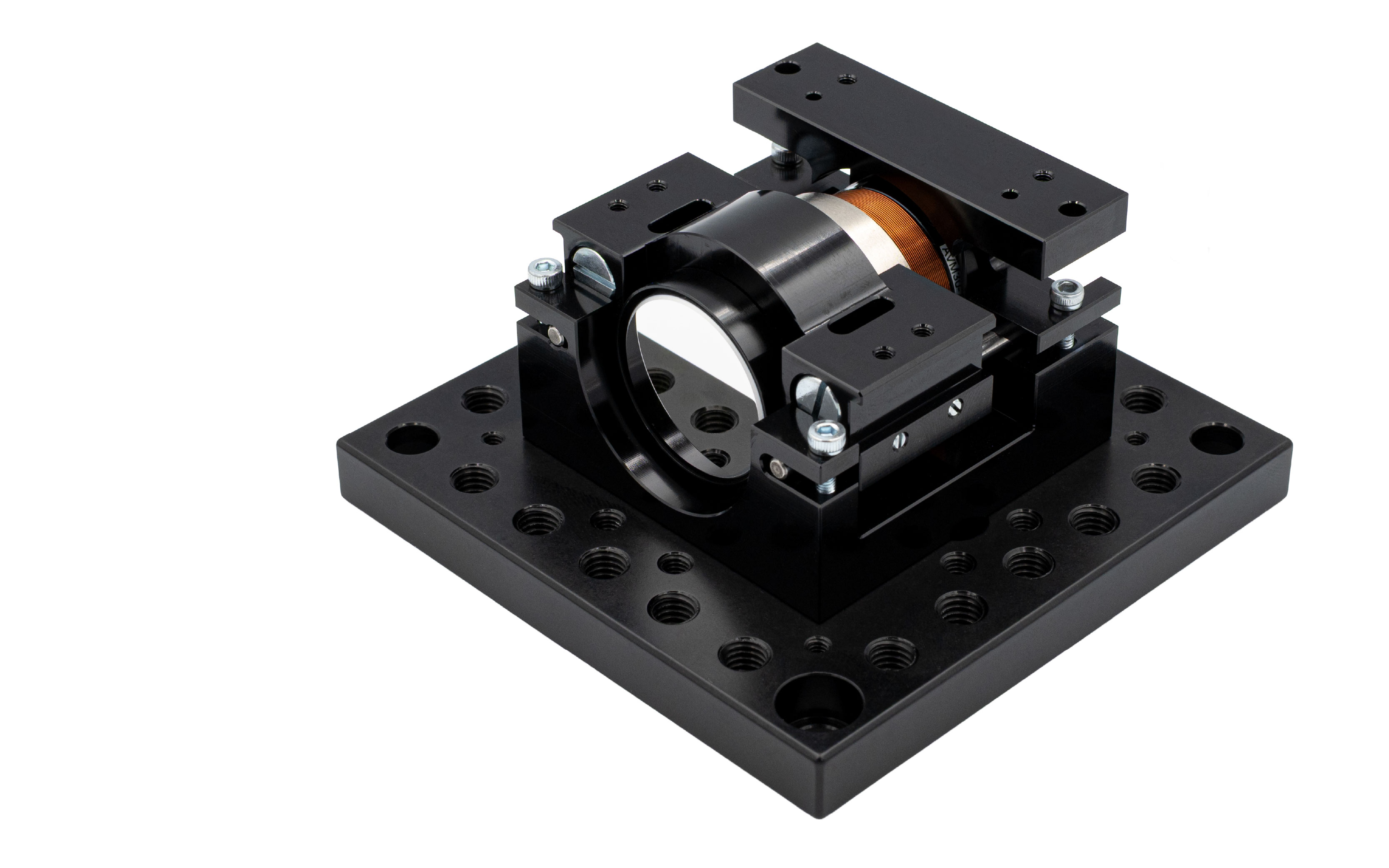

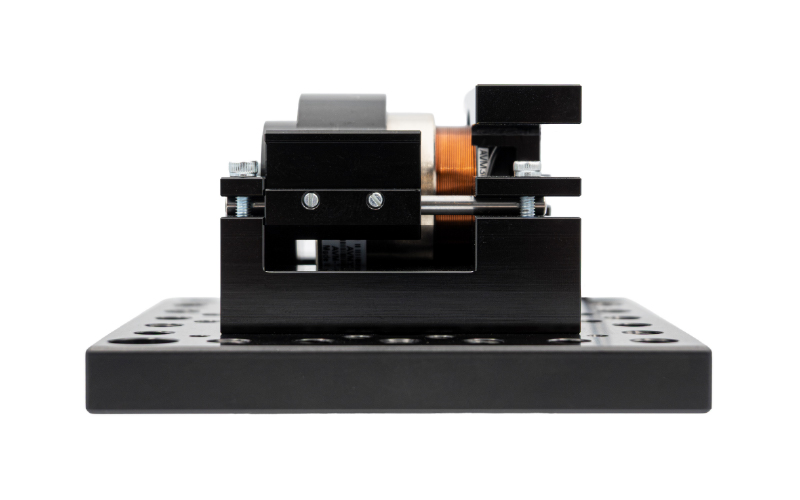

High-Dynamics Voice-Coil Positioner

Developed by MPS Microsystems, the voice-coil nano-positioner unites a Lorentz-force motor, flexure guidance and on-board electronics inside a 65 × 60 × 38 mm envelope. Standard travel is 2.88 mm, extendable to 7 mm with the same coil, suiting microscope objectives, small mirrors and sensors that demand friction-free motion.

Bidirectional repeatability stays within ±1 µm over a 360 µm stroke and ±2.5 µm across the full stroke. We can tailor mounting plates, objective clamps and cable exits to suit your specific requirements, ensuring that this Voice-Coil Actuator can be integrated seamlessly into your system.

Technical specifications

Z stroke | 2880 μm (extensible to 7000 μm) |

Z position accuracy | 360μm in 10ms: ±1μm / 360μm in 6ms: ±2.5μm |

Z minimal incremental motion | 40 nm |

Z max speed | 150mm/s |

Z peak force | 24.9 N |

Z continuous force | 5.62 N |

Fast AND precise

Combining high speed and precision in a compact system is often a major challenge – but we’ve mastered it.

The motor supplies 24.9 N peak and 5.62 N continuous force, driving the stage to 150 mm/s and up to 9 g. Closed-loop feedback resolves 40 nm increments; a 360 µm move settles to ±1 µm within 10 ms, and a full 2.88 mm return only requires 20 ms. The agility of this voice-coil nano-positioner lets microscopes hold focus during rapid XY scanning and allows metrology heads to correct step heights in real time.

Despite the speed, lateral deviation remains below ±1.5 µm and angular error under 70 µrad, keeping beam paths and sensor planes aligned. When using a ball bushing instead of a linear bearing, those values drop to ±1 µm and ±30 µrad respectively.

Platform technology

MPS Microsystems' technology is based on modular actuation platforms for precise lens positioning along different axes: axial (Z-axis), lateral (X and/or Y-axis), rotational (tip-tilt), or a combination of these. Each customer-specific solution is a scaled adaptation of our core technological platform, significantly reducing development time and costs.

To meet our clients' requirements, the following components can be customized:

• Selection of motor according to frequency, speed and acceleration requirements

• Ball screw or cam design and choice of ball bearings according to the required stroke

• Type of encoder and controller to match the required resolution

• Dimensional adaptations for a perfect match with the optical design.

• Adapters for precise positioning of fixed lenses.

• Bellows for high cleanliness