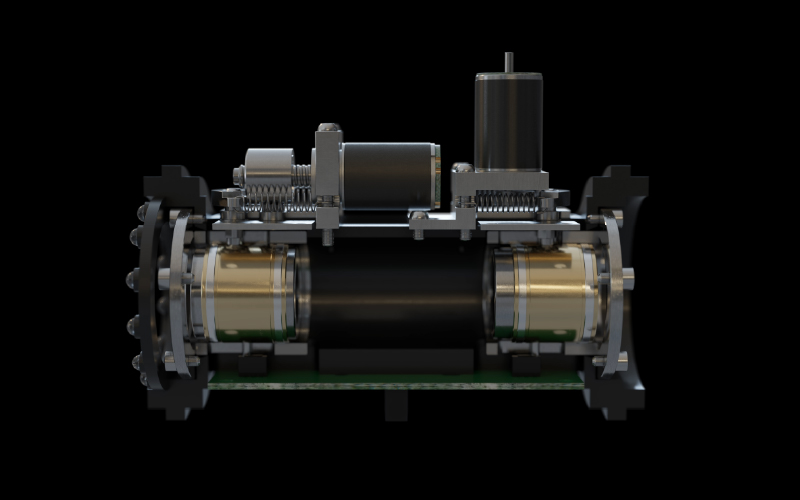

High-speed coaxial lens actuator

Designed on MPS Microsystems’ modular optomechanics platform, the High-Speed Coaxial Lens Actuator delivers custom-engineered, micron-level alignment in a footprint of just 170 × 87 × 45 mm. Two brushless motors drive lens holders (Ø 12.7 mm) that move in the same precision-machined bore, guaranteeing perfect coaxiality throughout the 3.75 mm stroke and no shimming or iterative alignment required.

The closed-loop cam mechanism runs friction-free, ensuring a maintenance-free stage that can be used in laser machining heads, spectrometers or 3-D scanners and keeps working for millions of cycles. Most importantly, stroke, motor, encoder and mounting interfaces of this high-speed coaxial lens actuator can all be customized to fit your needs with regards to optical and space constraints.

Technical specifications

Z stroke (per lens) | 3.75 mm |

Max lens diameter | 12.7 mm (½") |

Z position bidirectional repeatability | +/-3 µm |

Z position accuracy | 4 µm |

Lateral repeatability | +/-1 µm |

Lens holder tilt repeatability | 0.2 μrad |

| Speed | 15 mm/s |

Speed and precision - no compromise

Where most stages force you to choose, this actuator gives you both: translation speeds up to 15 mm/s and bidirectional Z-repeatability of ±3 µm, with lateral drift held to ±1 µm and tilt repeatability under 0.2 µm. Real-time feedback corrects every move, so the lens stack can focus in milliseconds without losing the optical axis.

The result is a system that can scan patterns quickly, maintain laser-spot quality and still land exactly on target. Our high-speed coaxial lens actuator the sweet spot for high-throughput systems that refuse to compromise on accuracy.

Platform technology

MPS Microsystems' technology is based on modular actuation platforms for precise lens positioning along different axes: axial (Z-axis), lateral (X and/or Y-axis), rotational (tip-tilt), or a combination of these. Each customer-specific solution is a scaled adaptation of our core technological platform, significantly reducing development time and costs.

To meet our clients' requirements, the following components can be customized:

• Selection of motor according to frequency, speed and acceleration requirements

• Ball screw or cam design and choice of ball bearings according to the required stroke

• Type of encoder and controller to match the required resolution

• Dimensional adaptations for a perfect match with the optical design.

• Adapters for precise positioning of fixed lenses.

• Bellows for high cleanliness