Bienne

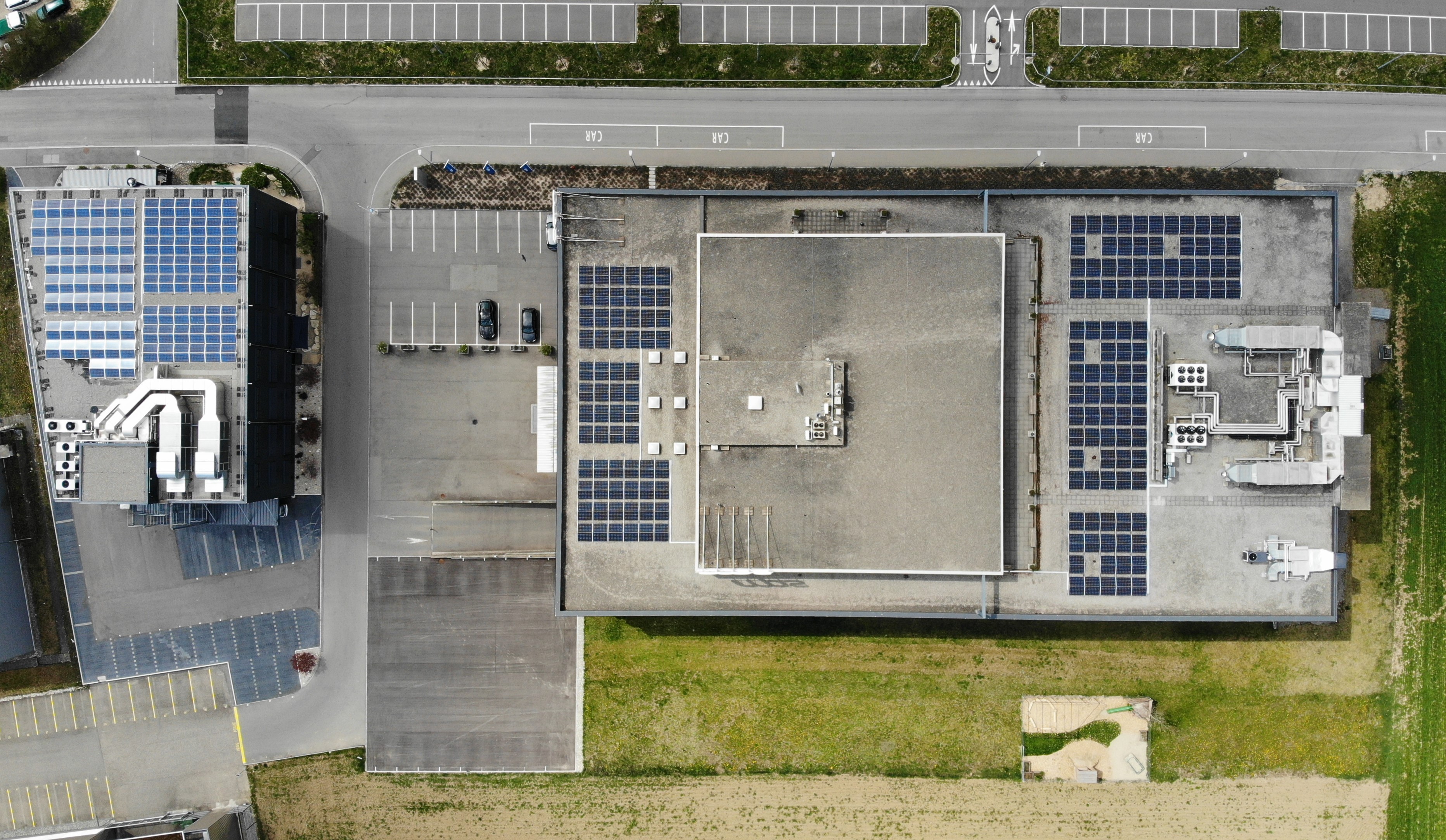

The headquarters of MPS are located in Biel/Bienne and consist of two buildings.

The first building was inaugurated in 2008 and covers and area of 14,400 m². The offices of management, administration, sales, quality and R&D are located in it. A large part of the production facilities is also based in these premises. On the roof of the building, 530 m² of solar panels with a maximum output of 249 kW provide clean energy.

In 2019, a second building was opened next to the first one. It accommodates a production unit as well as the offices of MPS Watch. Furthermore, the building is powered in part by a solar plant with a maximum power of 50 kW.

229

Employees6

Industries served

Watchmaking, Medical, Optics & Photonics, Automation, Science, Aerospace & Defense17'400m2

Area

Capabilities and equipment

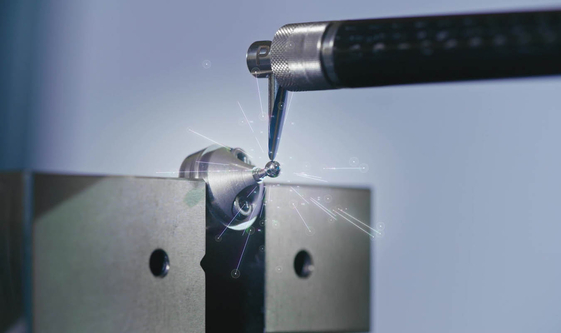

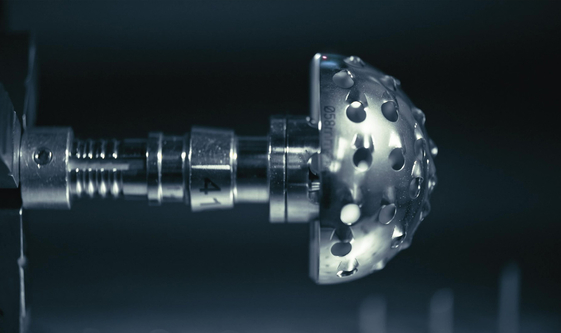

| Machining capabilities | Turning, CNC turning, 3-axis milling, 5-axis milling, drilling, machining of balls with Ø 0.15 to 1.5 mm, internal grinding, external grinding, flat grinding, lapping, polishing, wire EDM, sinker EDM, extrusion, sandblasting, milling, polishing, laser marking, laser welding, laser cutting | |

| Used materials & alloys | Stainless steels, titanium, aluminium, brass, bronze, copper, plastics, ceramic, other metals | |

| Assembly techniques | Development of product-specific assembly lines, clean room ISO 7, pairing in 0.25 μm steps, riveting, pressing, bonding, preicision lubrication, laser welding, balancing, manual assembly, TIG welding, engraving, customer-specific testing and measuring | |

| Specific equipment | Grey room, clean room, oil room, thermal and superficial treatments, automatic washing, passivation | |

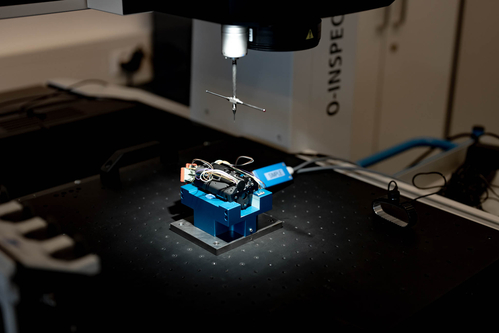

| Metrology | Optical and tactile three-dimensional control; roughness, shape and roundness measurement; optical scanning; measurement bench; conventional metrology; metrological calibration center |

| R&D | Development engineers, lab engineers, precision mechanics. Solidworks, risk assessment (DFMEA), design/prototyping/verification/validation, rapid prototyping (laser cutting, 3D printing), methods team, operational excellence team | |

| Testing methods | Development and production of testing equipment, friction torque tests, load tests, lifetime tests, performance tests, thermal tests, cross-sectional analysis | |

| Process engineers | Development of production processes, development of assembly processes, risk evaluation processes | |

| Validation engineers | Process validation, equipment qualification | |

| Industry 4.0 (visual management) | SAP, FORCAM, Kardex | |

| Certifications | ISO 9001:2015, ISO 14001:2015, EN ISO 13485:2016 |

Our cutting-edge equipment

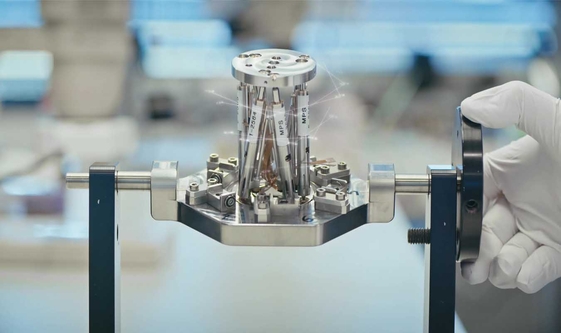

MPS has two cleanrooms for the assembly of delicate, dust-sensitive parts.

Our ISO 7 cleanroom covers an area of 200 m². It is mainly used for the assembly of components for the medical sector, in particular for the peristaltic pump. Other miniature components for the aerospace and defense markets are also assembled here.

Since 2024, we also have an ISO 5 cleanroom. 100 times cleaner than ISO 7, this new cleanroom is dedicated to the semiconductor sector.

MPS contributes to protecting the climate

In an effort to contribute to the climate crisis, MPS has installed solar panels on the roof of all its buildings. Through the ISO 14001 certification – Environmental management system, we affirm our commitment to building an sustainable future for the planet and our employees.

Several measures have been taken in order to achieve our sustainability goals. For example, all the lights of our main building have been replaced by a newer, more economic solution. Furthermore, disposable plastics have been banned. At each level and in each division, many more actions were taken in order to create a large impact.

1000+ m2

area of solar panels299 kW

combined solar power