Electronics

MPS Microsystems develops advanced components and systems for various demanding applications in the field of electronics. Our expertise in manufacturing, assembly, and cleanliness makes our solutions indispensable assets in our customers' high-volume assembly and semiconductor inspection equipment.

We manage complex projects from concept to mass production and work with our extensive network of reputable partners to deliver systems that push the boundaries of what is possible. This enables us to provide customized solutions that stand out for their precision, dynamism, and cleanliness.

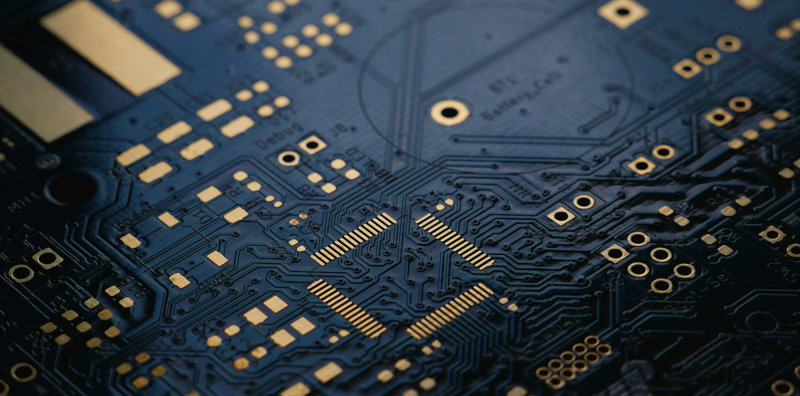

High-volume assembly equipment

For nearly 20 years, MPS Microsystems has been manufacturing grippers for pick & place heads used in high-volume assembly machines for printed circuit boards and surface-mount technology (SMT) components. These grippers are subject to increasingly stringent manufacturing requirements due to the constant miniaturization of electronic components.

Our expertise in linear and rotary bearings is key to this product. To meet the customer's requirements for smooth operation, precision, and stiffness, the components are ground, polished, and then assembled by pairing within a precision range of 0.25 µm using balls graded in 0.2 µm groups. Stiffness is also ensured by the preload of the bearings.

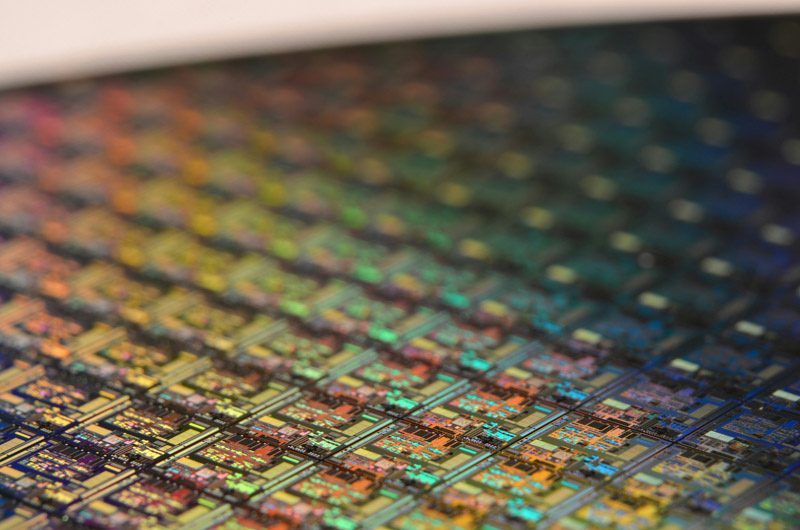

Semiconductor inspection equipment

The strong growth in demand for electronic devices is prompting semiconductor manufacturers to rethink their supply chains. MPS Microsystems is relying on its strength in process innovation to help reduce the inspection time for the various components used in semiconductor production.

The multi-layer systems we have developed in partnership with leading scientific institutes undergo various stages in our ISO 5 clean room, including brazing, ultra-high vacuum baking, and magnetization. Assembled on a ceramic base with a tolerance of ±2 µm, these parts form a system that enables our customers to build high-performance reticle and wafer inspection systems.

Photonics Integrated Circuits (PIC)

Photonics Integrated Circuits (PIC) have the potential to revolutionize various sectors of electronics thanks to their efficiency, high information transfer capacity, and small size. In addition, since optical signals are insensitive to electromagnetic fields, these systems can be used in applications subject to strong interference.

MPS Microsystems is contributing to the development of Photonics Integrated Circuits by positioning itself as a trusted partner for the assembly and integration of systems into their housings and final applications. Our extensive experience in micro-assembly and cleanliness enables us to skillfully manage packaging projects for instruments in the fields of medical imaging, biotechnology, and defense.

Academic partners

Over the years, we have built up a large network of academic partners with whom we collaborate to develop state-of-the-art solutions.

• PSI - Paul Scherrer Institute

• EPFL - École Polytechnique Fédérale Lausanne

• ETHZ - Eidgenössische technische Hochschule Zürich

• HES-SO - Haute école supérieure de Suisse occidentale

• OST - Ostschweizer Hochschule

• University of Berne

• CSEM - Centre Suisse d'Électronique et de Microtechnique

• EMPA - Swiss Federal Laboratories for Materials Testing and Research