Oscillating weights

In order to optimize the supply chain of our customer factories, we have now integrated the production of tungsten and precious metal oscillating weights.

MPS is thus able to supply a complete assembled rotor integrating a reliable high performance bearing and an oscillating weight of its own manufacture.

Thanks to our daughter company Charly Veya SA, specialized since 1960 in stamping, we have the production capacity to make stamped parts. A very large variety of materials and aesthetics are thus possible.

Benefits

- One interlocutor to simplify the supply chain and quality control

- Perfectly controlled rotor play and beat

- Numerous technical and aesthetic possibilities

- An integrated production: stamping, manufacturing and finishing

- An automated, independent, ISO 9001 and ISO 14001 certified production

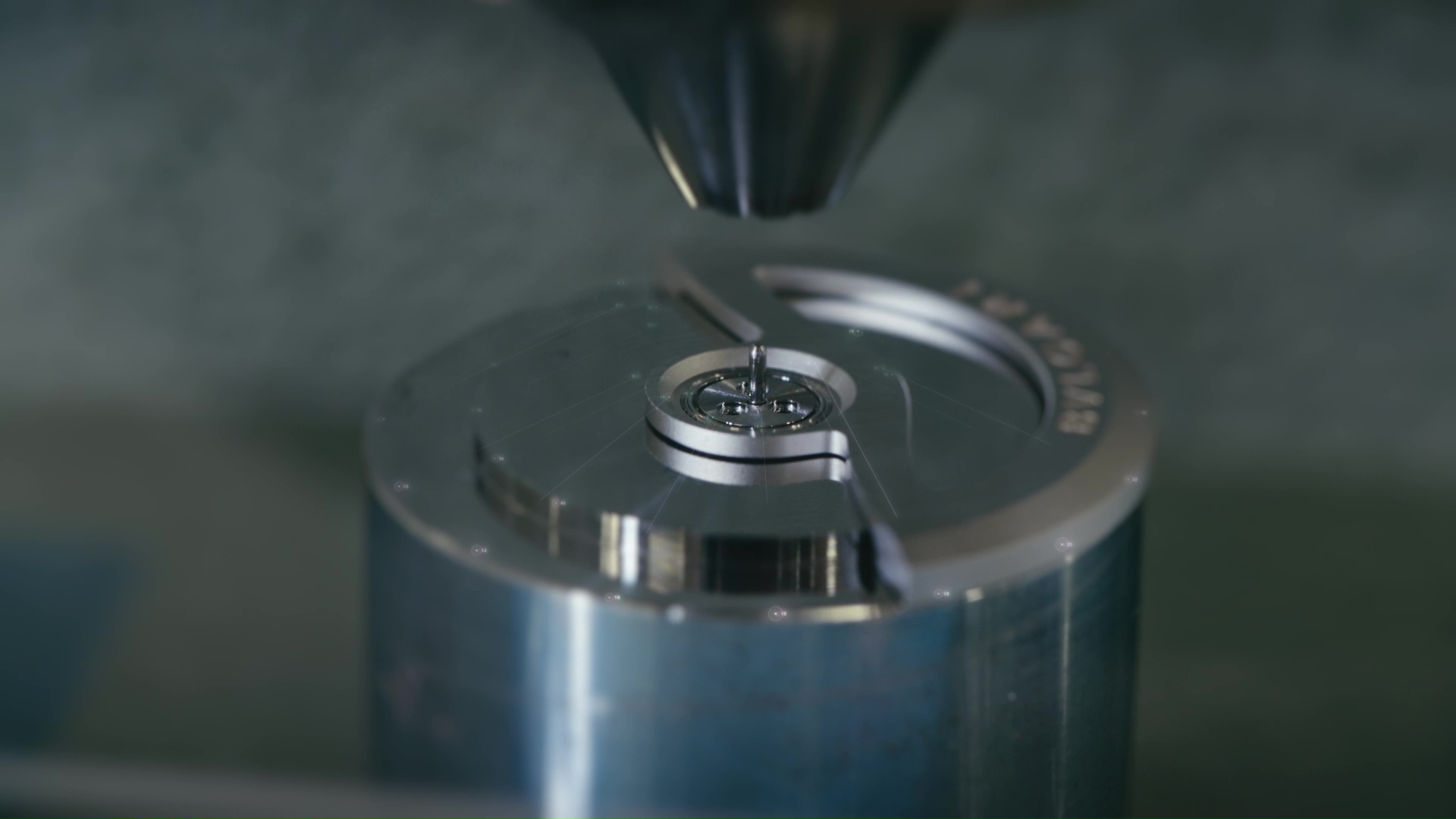

Weight assembly

Assembly of the oscillating weight by press-fitting and/or riveting can appear simple at first sight. And yet, if this operation is not very well controlled, it can result in high scrap levels. This is why more and more brands have decided to entrust this operation to MPS Watch.

In this operation, and even if the part with the most added-value is the oscillating weight, engineers building movements do well to remember that the essential function is performed by the ball bearing.

A team listening to your concerns

We’ve noticed that assembling the weight on the bearing can cause significant scrap levels at some of our customers. Our engineers’ response, as specialists in micro-assembly, was to develop models and processes to predict the influence that press-fitting and riveting will have on operating play in the bearing while also considering the different materials used. Thus, MPS Watch is able to guarantee a reliable and repeatable assembly process without generating any scrap due to the operating procedure. Finally, optimised logistic management provides responsiveness and flexibility.