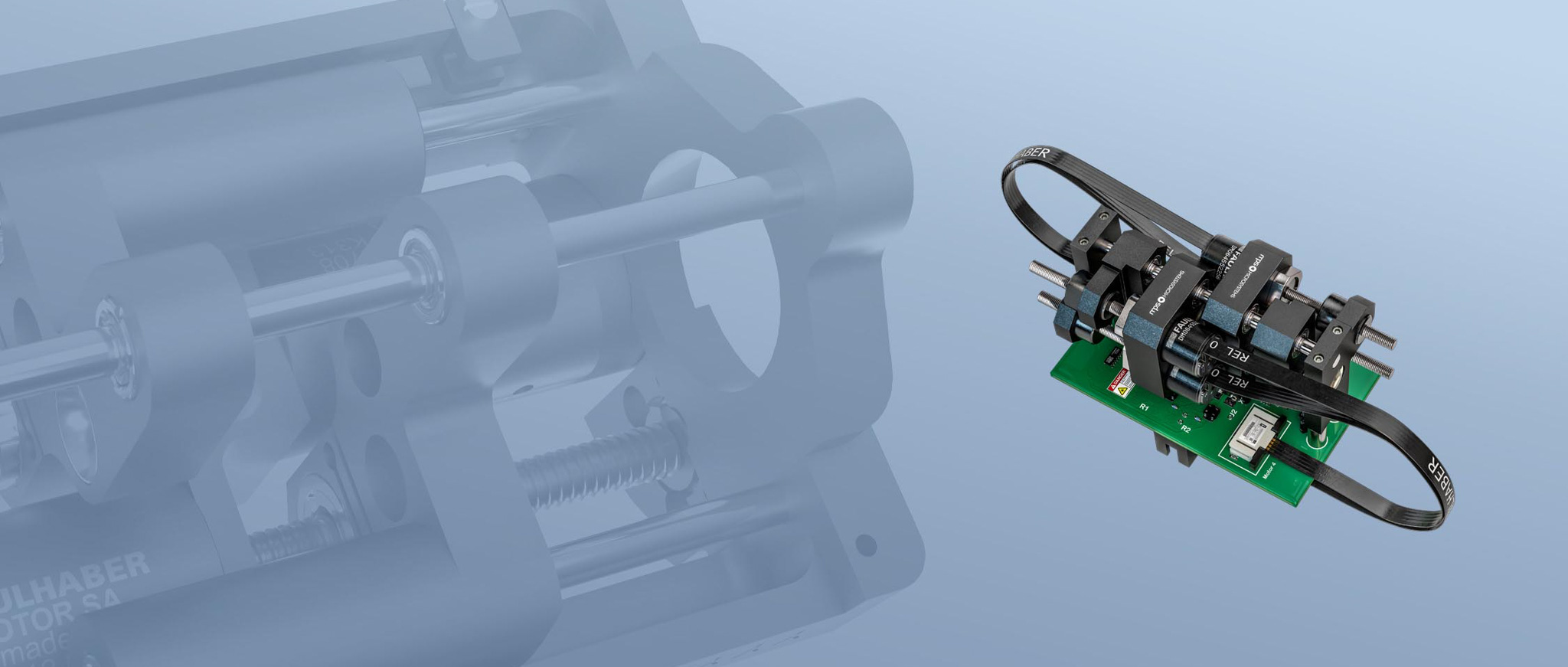

Optomechanical system for linear displacement of several lens groups

Offering its customers a custom-made high-performance optomechanical system in a few weeks is the challenge that MPS Microsystems has taken up by developing its latest innovation, a high-precision configurable platform composed of several miniature lens actuators operating on the same axis.

Depending on the desired configuration, this system allows to move very precisely 1 to 4 sets of lenses (carriage) over a stroke of a few millimeters to several centimeters. The design has been optimized to ensure perfect coaxiality of the lenses and minimize the tilt throughout the movement. This electromechanical system mainly consists of MPS and FAULHABER high-precision standard modules, such as DC motors, lead screws or ground ball screws with double nuts and linear ball bearings.

It is particularly recommended for focusing a laser over a long stroke, for example, for guidance of unmanned flying objects or for the communication between flying objects. Such a system is also ideal for moving the optics in stereoscopic surgical glasses.

The number of carriages, lens size and stroke can be configured as desired. For higher precision, the fixing of the axes in a rigid aluminium frame guarantees perfect stability and therefore improved optics. If necessary, the integration of encoders for closed-loop management makes it possible to achieve repeatability in the micron range.

Characteristics

| Dimensions: | 38 mm x 27 mm x 23 mm |

| Weight : | 21 grams |

| Number of mobile carriages : | 4 |

| Stroke : | 2.5mm per carriage |

| Material : | Aluminum and steel |

| Drive : | 4 FAULHABER 6mm stepper motors (DM0620) |

| Translation : | Lead screw M1.2 x 0.25 |

| Guides : | MPS linear ball bearings type L204X |

| Maximal speed : | 30mm/s |

| Repeatability : | 10 µm |

| Lens diameter : | Max. 4.5 mm |

| Rigid frame : | No |

| Encoder : | No |