MPS Décolletage

Located in the Jura around Bern at Court, the cradle of the Swiss micro-turning industry, MPS Décolletage has maintained the tradition of the art of high precision turning since 1929.

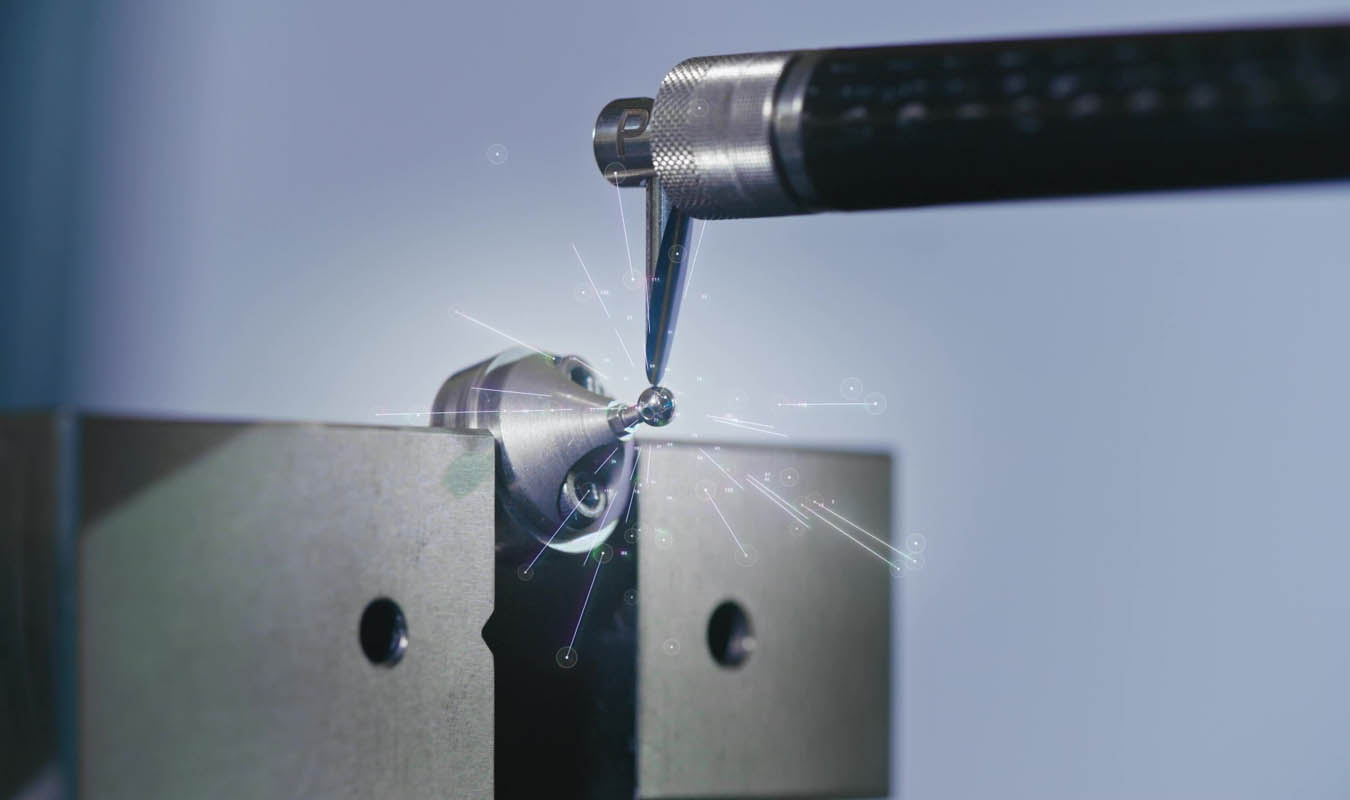

On customer instruction, MPS Décolletage produces parts meeting the most demanding specifications for complexity of forms, dimensional and geometric tolerances, surface quality and finish.

Its employees' high level of training, optimisation of manufacturing processes and efficient organisation enable MPS Décolletage to offer competitive prices and delivery times.

Our strengths

- High service level

- Quality, repeatability and reliability of products

Links

- Request for information

- MPS Quality

- Subcontracting service

- Find your contact

Download

- Brochure - MPS Décolletage

PDF

Main supplier of MPS Watch

MPS Décolletage supplies the MPS Watch division with complex parts designed for the movements of mechanical watches. Most of the turned parts for MPS Watch are made on the MPS Décolletage site at Court. Control of all the production steps enables MPS Décolletage to offer a perfectly finished, high quality product.

Our commitment to quality, your added-value

Quality inspection is adapted to our customers' specific needs. Throughout the process, periodic inspections are performed to ensure full product traceability. A detailed manufacturing inspection protocol based on SPC method (Statistical Process Control) can be supplied with each delivery. Material, treatment and coating certificates are also available on request.

Skills serving you

MPS Décolletage manufactures small, medium and large production runs of high precision turned parts in diameters ranging from 0.2 mm up to 51 mm in various materials such as cuprous alloys, mild and stainless steels, aluminium, titanium and all machinable materials.

A select subcontracting service

Our main motivation is to satisfy our customers' requests, as demanding as they are, to ensure their success in the market. Benefit from our capabilities in manufacturing, machining and component assembly processes.