Court

Since 2015, MPS Décolletage has been located in an eco-friendly 3,400 m² building powered by solar panels. The panels cover an area of over 1,250 m² and deliver a maximum power of 225 kW, which represents an annuel capacity of around 215 MWh.

This intelligent building manages all thermal flows and provides ideal climatic regulation in all departments. Material stocks are computerised and contribute to strict management of the manufacturing flow. Traceability is guaranteed throughout the manufacturing processes.

52

Employees4

Industries served

Watchmaking, Connector technology, Medical and Industry3'400m2

Area

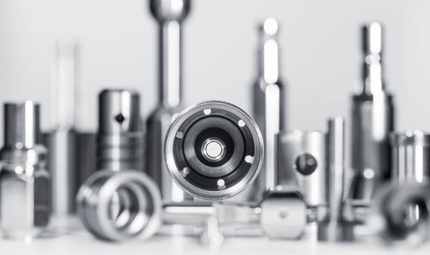

Capabilities and equipment

| Cam-operated machines | 39 (Tornos M7, M57 and R10) | |

| CNC lathes | 61 (Citizen, Hanwha, Schaublin, Star, Miyano) | |

| Capacity | 15 M parts | |

| Machining capabilities | Dimensional capabilities in production : 0.2 mm to 51 mm diameter Passage capacity : 0,8 mm to 51 mm diameter | |

| Used materials & alloys | Brass, bronze, medical-grade stainless stell, titanium, aluminium, Inconel, ETG100, PEEK, other materials on demand |

| Specific facilities | Surface treatment (trovalisation) | |

| Industrie 4.0 (visual management) | SAP, FORCAM, Kardex | |

| Department | Methods team, continuous improvement, machining techniques | |

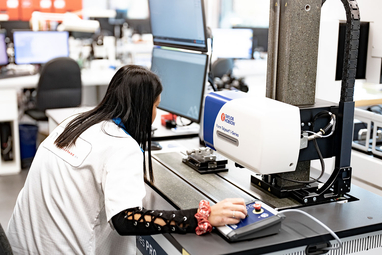

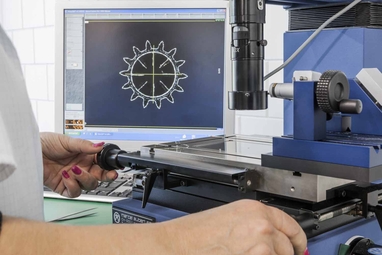

| Metrology | Marcel Aubert projectors, Talyron, Taylor Hobson contour graph, roughometer, Sylvac & Trimos test bench, Zeiss O-Impact 3D machine (probing, optics, DotScan) |

Our cutting-edge equipment

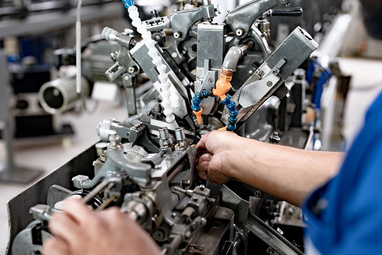

Several automatic CNC lathes and cam-operated turning machines work 24 hours a day to produce turned parts with very high requirements. To produce parts with very complex geometries, these machines are equipped with specific devices and peripherals to enable high frequency machining, polygon machining, whirling, high pressure drilling and precision gear cutting for wheels and pinions.

MPS contributes to protecting the climate

In an effort to protect the environment, MPS Micro Precision Systems AG has installed solar panels on the roof of its building in Court. Through the ISO 14001 certification (environmental management system), MPS commits to a sustainable future for the planet and its employees.

Moreover, MPS has contributed to saving bees by installing 3 beehives next to the building. The bees that live there produce between 20 and 30 kg of honey a year.

1000+ m2

Area of solar panels165 kW

Power of solar panels3

Beehives

20-30 kg honey / year