Bonfol

Based in Bonfol since 1967, MPS Watch doubled its production area in 2013 by building a new factory. Modern and ecological, these new premises were joined in 2018 by a completely renovated original building which optimizes the energetic performance of the site. The new building intelligently manages thermal streams and thus allows an ideal temperature regulation across all zones.

Through the ISO 14001 certification (environmental management system), MPS Watch commits to a sustainable future for the planet and its employees. On the roof of the building, a solar system with a maximum output of 290 kW has been installed. It covers an area of 1200 m² and is designed to produce 290'000 kWh of electricity per year. 90% of this energy is directly used by MPS Watch.

176

Employees1

Industry served

Watchmaking7'000m2

Area290

kW

Capacities and facilities

| Turning | 26 CNC machines (Tornos, Star, Miyano) | |

| Milling | 5 3-to-5-axes HSM machines (GF) | |

| Wire erosion | 2 CUT1000 OilTech machines (GF) | |

| Post-processing | 10 gear-cutting machines 6 rolling machines Thickness setting | |

| Finish | Tribofinishing, laser finish, sunray finish, circular finish, satin-finish, diamond polishing, grained finish | |

| Used materials & alloys | Stainless steel, Finemac, Law 100 X, 20AP, brass, BeCu, Declafor, nickel silver, Ecobrass |

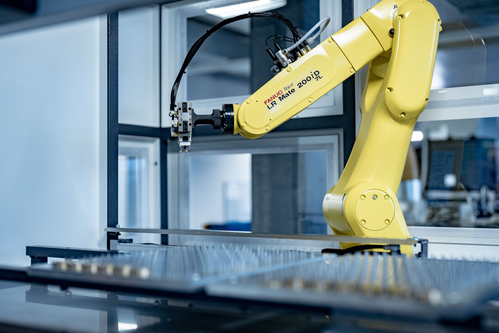

| Assembly | Automatic and hand assembly, laser welding, push-fit, riveting, mass assembly | |

| Specific facilities | Grey room, thermal treatment, automated washing lines | |

| Industry 4.0 | Lean manufacturing, SAP, Forcam Force, PLM, shop floor management, Kardex, e-shop | |

| Engineering | R&D, methods & industrialization, laboratory, equipment development, quality and continuous development, mecanics | |

| Control & metrology | QuickControl, SPC, optical control machines, micro-torque measurement, interital tolerancing, 3D Zeiss measurements |

Our state-of-the-art equipment

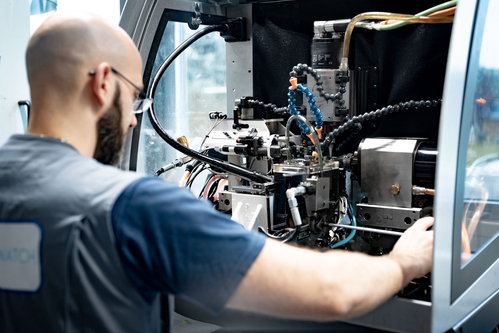

To better meet the specific requirements of our clients in terms of quality, precision and reliability, MPS Watch counts on its modern machines and a network of dependable partners. Our technical team develops complex and unique machines that are tailored to perform diverse watchmaking tasks, notably machining, finishing, and assembling. Lean Manufacturing, Industry 4.0 and SPC are the pillars of our flexible and performance-oriented organisation. Thanks to our expertise in high-precision micromecanical assembly techniques, MPS Watch masters the production of all watch components.